Whilst part two of this series was a model of brevity the same cannot be said for this, the final part!

Undercoated. I usually only apply a single coat of white at this stage although anything that will be white at the finish usually gets at least two coats. If you look closely you can see that the top deck section (bottom left) that the edges have been given a second coat as this will the white line of the upper hull - see the finished model to see what I mean (top left).

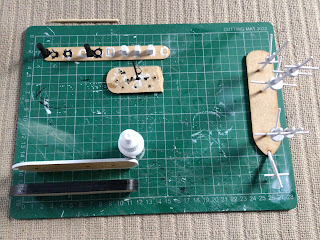

For the next step I tend to paint the lower hull, the funnels and what will eventually be the gun barrels - these are all painted Vallejo black. The deck features will be painted Vallejo dark sea grey whilst the deck itself will be Vallejo tan earth. As mentioned previously I always complete everything on the deck - including assembly - before the mast and bowsprits are fixed in place.

The hull and white edge of the top deck have been painted along with the funnels and the cocktail stick that will be used for the gun barrels

The deck features are painted in Vallejo dark sea grey. The hull has a section of the bow painted as this is visible through the bowsprit notch. Once the bowsprit is fixed in place you can not see it anyway but I like to do this in case you can!

The top deck added to the hull. Now you can see the advantage of painting prior to glueing it to the lower hull - the white line is ramrod straight!

The first part of this stage is to paint the hatch covers, gun carriages and the funnel base before adding the deck to the hull and painting it. It is easier holding a four layered hull when painting any detailing!

Once the hull and deck features are dry one can look to paint the deck itself. I would also point out that you can see the advantages of having straight lined features rather than circular. It is easier to paint around a square or rectangle than a circle so the addition of a funnel base is more for convenience than accuracy!

The lower hull painted and ready for the deck features

The first step when making a gun barrel is to file the end into a rounded shape

The filed end is then touched in with black paint

A 10mm length is cut off and is glued in place on the previously fitted gun carriage. I fix this about halfway down the barrel so around 5mm with a 5mm overhang. Note that the two gun carriages clear the mast holes by a couple of mm.

With the gun barrels in place and the funnels fitted the hull is set aside to dry so that painting of the masts can commence.

The subject of masts and rigging is a major study all of its own and would require far more effort than I would want to spend. For the most part I have just ‘winged it’ but the end result looks fine so that will do for me! Painting wise I usually go for Vallejo Iraqi sand for the exposed woodwork of the masts along with black for the spars. Very simple, clean looking and believable - or in other words, ‘purely representational!’

The hull has been varnished and the masts have had the first part painted - the bare wood - and these will be varnished once fixed in place.

Once the masts and bowsprit have been painted the next step is to fix them in place on the hull. This is where the pre-drilled holes come into their own as a drop of super glue on the base of the mast and voila! They are done. Needless to say, care needs to be taken to ensure that they are square in place.

At this point I should have included a picture of the masts fully painted before being fitted to the hull. Sadly I forgot to do this and instead went straight ahead and fixed the masts in place! For the record I tend to fit the bowsprit first followed by the mizzen, the main and the foremast last of all.

Once the glue has hardened off the masts can be varnished, again using my preferred satin varnish. The ensign is added as the final step and is also varnished and hey presto - C.S.S. Florida is ready to sweep the seas of Union shipping!

Viewed from the bow….

….and the aft quarter.

Viewed from the beam. For reference the hexes are four inches between the flat sides

Lessons Learned

Going forwards I shall be painting masts and spars separately and prior to assembly!

Now for the remaining Lake Tanganyika models in advance of industrial quantities of MDF arriving for the ironclads.

8 comments:

A very interesting set of "How to.." posts. Thanks for sharing your construction methods. The finished model is really nice.

Hi Maudlin Jack Tar,

Many thanks old chap! I have enjoyed writing them and in truth have learned a few things whilst doing so. Certainly the ironclad build will incorporate some lessons acquired during the build!

All the best,

DC

Cracking tutorial and a grand outcome, the finished model is very nice. Always good to learn the thought process behind a build. Great stuff!

Thanks Donnie! I am glad I did it and thinking out loud via the blog is always helpful.

All the best,

DC

You make it seem so easy…

All the best. Aly

Hi Aly,

I will let you into a little secret - it is! I would attach a minor caveat to that though - they are only easy if you let them be and by that I mean leaving out heaps of extraneous detail!

All the best old chap,

DC

That's a very handy guide. Thanks DC

Hi Jim,

Many thanks old chap! I must admit that I rather enjoyed the process and it was certainly a good workout for my modelling genes!

All the best and thanks once again,

DC

Post a Comment